Production

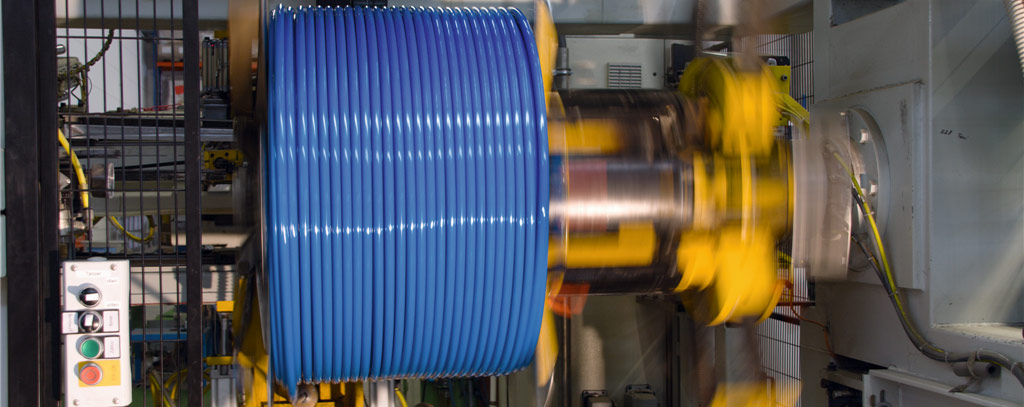

The base material for the production of our gabotherm PE-Xc pipes is PE-HD (high density polyethylene). We use it to produce 3 or 5-layer pipes in a co-extrusion process. Then the pipe that is already oxygen proof is treated by means of electron beam crosslinking.

This process ensures that the plastic’s macromolecules are physically bound together. This quality-enhancing process guarantees highly stable, temperature-resistant and durable product. In the layer composition of the 5-layer PE-Xc pipe, the centrally located oxygen barrier is ideally secured against mechanical damage.

Technical Data

- Max. operating temperature 90° Celsius *

- Max. operating pressure 10 bar *

- Min. bending radius 6 x d

- Thermal expansion 2,0 x 10-4 1/K

- Installation temperature > +5° Celsius

* these maximum numbers do not apply to combinations

| Pipe Dimension | Water Content | Weight per 100m |

|---|---|---|

| 14 x 2.0 | 0.08 l/m | 8.3 kg |

| 16 x 2.0 | 0.11 l/m | 10.0 kg |

| 17x 2.0 | 0.13 l/m | 10.6 kg |

| 18x 2.0 | 0.15 l/m | 11.2 kg |

| 20 x 2.0 | 0.20 l/m | 12.5 kg |

| 25 x 2.3 | 0.33 l/m | 18.5 kg |

Customized dimensions and requirements on request.

Areas of Application

- Mainly in area heating

- Ideal for industrial area heating and activation of building components

- Radiator connection

- Sanitary installation (pipe dimensions on request)

Advantages

- Durability

- High stress cracking resistance

- High pressure stability

- Temperature stability

- Impact resistant and abrasion-resistant